Role of Piston Skirts In Diesel Engine

Piston skirts is an important part of piston which covers the lowest. Piston skirt is responsible to keep piston from shaking unreasonably within the cylinder during working. Providing proper lubrication is the main task of Piston Skirts by holding and transporting oil to wall of the cylinder. To prevent scuffs on cylinder wall chemical layer coating is made on Piston Skirts which helps in proper lubrication.

Especially Heavy Diesel Engines requires proper lubrication in the cylinder walls and it requires special Piston Skirts which can perform lubrication process in heavy diesel engine.

Therefore, PIA has introduced High Performance diesel engine overhaul Piston Skits.

PIA’s Piston Skirts

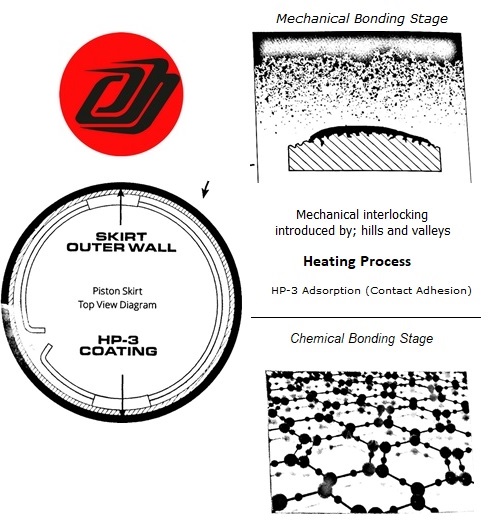

PAI’s Piston Skirts are treated with a new and highly developed anti-friction coating process. The coating is designed to lower scuffing and wear while providing a dry lubrication that is highly resistant to contamination, and reduces parasitic drag. HP-3 is a proprietary formulation of anti- friction coating applied to the piston skirt, to decrease friction on the cylinder walls.

As the largest friction area, the Cylinder Wall represents the largest loss of power and efficiency anywhere in the engine. HP-3 coating drastically reduces friction and allow for tighter clearances between the piston and the Cylinder Wall. This reduction in friction and clearance improves overall performance, lowers oil usage and oil temperature; ultimately increasing the life of the Skirt.

“HP-3 Coating drastically reduces friction and allow for tighter clearances between the piston and the Cylinder Wall.”

Hp-3 Dry Film Lubricant

Coating Process

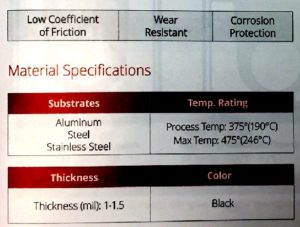

HP-3 Dry Film Lubricant coating is applied as a spray process. Different surface preparatory methods appropriate for the substrates are used prior to the coating process. Coating thickness is varied to suit the application. Typical coating thickness for piston skirts is 1 to 1.5 mil (12 to 37 microns).

Advantages

Low coefficient of friction, provides intermittent dry lubrication, Increased load carrying capacity, wear resistance, corrosion protection.