Navistar DT466 Engine Specifications & Application

Navistar DT engine Series consists of 6 mid-range Diesel Engines. So, the horsepower ranges from 130Kw/170hp to 260KW/350hp. DT series engines are part of medium range heavy duty automotive like trucks, school buses, and other buses applications. Whereas other engines serve in the service applications.

Navistar International previously known as International Harvest company was producing diesel engines mainly for Agricultural and construction equipment.

The dt466 engine being considered legend among DT engine Series because of its endurance and performance. There is a famous saying regarding DT466 that:

“If DT466 isn’t Enduring than we don’t what is”.

With a displacement of 466 cubic inches, DT466 is Six-Cylinder, four cycle Diesel Engine. Bore size and stroke of DT466 are 11.6.5mm*118.9mm (4.59*4.68 inches). With the compression ratio of 16.5:1. At 1900 rpm it produces maximum 260HP output while at 1400 rpm the maximum torque output is 800 ft-lbs.

DT466 engine aspiration system turbocharged with wastegate technology. Also with air to air intercooled design. This is Because of its fuel injection combustion technology. DT466 Engine governed speed 2500rpm estimated.

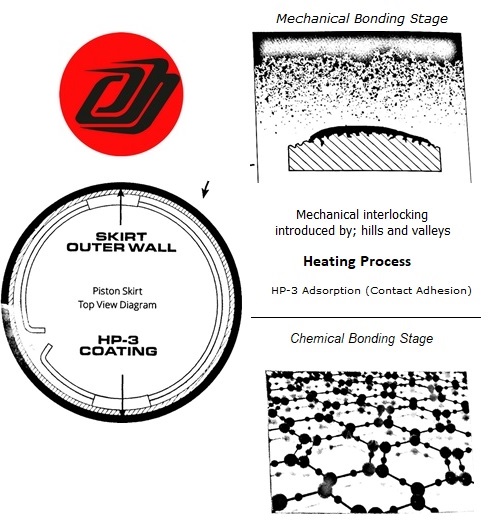

Navistar Introduced Wet Sleeve design into diesel Engines. In this model, they created cylinder walls/sleeves as the separately machined part which helps and fits exactly into the upper counter bore it helps in sealing at the top with O-ring housing bores are cast into the engine block in the bottom.

Major Update In International DT Engine Series

In 2004 major update was made into DT engine series to meet the emission standards set by the Environmental Protection Agency of USA. For this purpose, a new EVRT turbocharger technology did introduce with movable turbo vanes which helped in improved boosting and reduced the lag. Improved electronically controlled hydraulic unit fuel injection system along with a new four-valve cylinder head and an exhaust Gas Recirculation to reduce emissions.

Despite its endurance from a mechanic point of view Wet Sleeve engines do require in chassis overhauls after the specific period.